Harley Davidson has long been known for its iconic motorcycles, with a loyal fan base and a rich history dating back to 1903. However, even the most renowned and well-designed machines can encounter issues, and one area of concern for some Harley riders is the hydraulic clutch system.

This system, introduced in the early 2000s, was meant to provide smoother and more reliable shifting but has been met with mixed reviews and complaints from riders.

Here, we will explore Harley Davidson hydraulic clutch problems, the possible causes behind these issues, and the recommended solutions. Whether you are a long-time Harley rider or considering purchasing one, understanding the potential problems with the hydraulic clutch system is essential in maintaining a smooth and enjoyable riding experience.

What Is A Hydraulic Clutch?

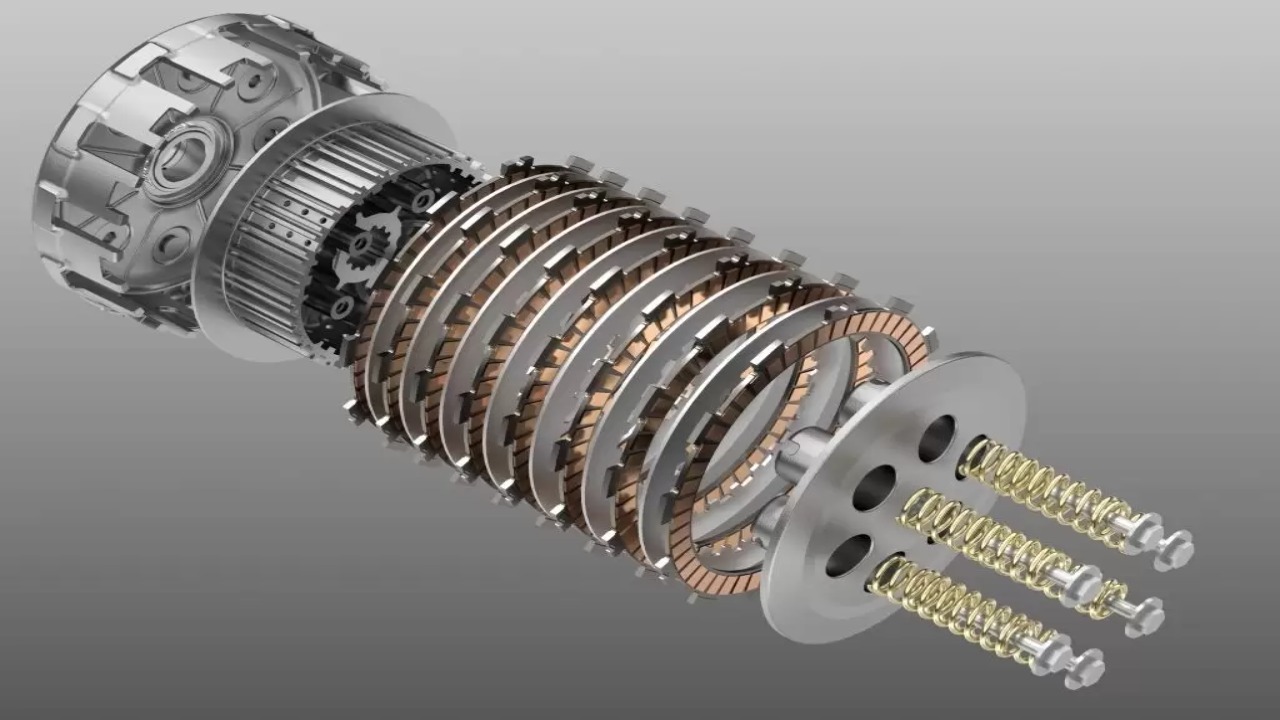

A hydraulic clutch is a force-reduction system used in Harley-Davidson motorcycles to reduce the force required to operate the clutch. It typically comprises the clutch master cylinder, slave cylinder, and a reservoir to hold the hydraulic fluid.

When hydraulic pressure from the clutch master cylinder increases, fluid flows from the master cylinder into the slave cylinder, causing it to press against the piston. The slave piston then transfers this force to the clutch disc, disengaging it from the transmission.

Hydraulic clutches are an advanced technology for reducing engine wear and increasing fuel efficiency and performance. They are also popular as electronic clutches or hydraulically activated clutches. Hydraulic clutch technology has been refined and improved over time by automakers and motorcycle manufacturers to offer more features and advantages, including better fuel economy and reduced emissions.

How Harley Davidson Hydraulic Clutch Works

The Harley-Davidson hydraulic clutch system has several components that work together to create the force needed to engage and disengage the motorcycle’s transmission. The clutch master cylinder houses a piston pressuring oil from the hydraulic fluid reservoir to operate the clutch plates.

When you apply pressure on the pedal, these forces oil out through lines connected to each of the motorcycle’s gears and into between these plates, which causes them to slip and rotate. Several problems can arise with the Harley-Davidson Hydraulic Clutch. These issues may be due to worn or damaged components, contamination in the system, or improper maintenance. Here are some solutions for these problems:

- Clean The Clutch Fluid Reservoir And Lines: First, check the reservoir for contamination. If it is contaminated, clean it thoroughly and replace any contaminated fluids or seals. Next, clean the lines that lead from the reservoir to the clutch seals master cylinder to remove debris and debris buildup.

- Replace Worn Components: If worn out or damaged, you should replace them. This can help maintain the proper functioning alignment and pressure of the fluid in the clutch master cylinder and lines and prevent leakage.

- Check For Proper Maintenance: Proper maintenance includes regularly checking fluid levels in the reservoir and replacing parts as needed. This will help to keep the clutch in good working order and prevent common problems like contamination.

Causes Of Harley Davidson Hydraulic Clutch Problems

A Harley-Davidson motorcycle’s hydraulic clutch system is one of the most important. This system controls the clutch pedal, which allows the rider to change gears while riding. A faulty hydraulic clutch can lead to various issues, including reduced engine performance and increased wear on other parts. Here are some common causes of hydraulic clutch problems on a Harley Davidson.

- Damage To The Fluid: Damage may occur due to leaks or improper maintenance. If the fluid leaks from an o-ring seal or is damaged, it must be replaced immediately.

- Clutch Cable Wear: The clutch cable clutches are a key component in any hydraulic clutch system and must be maintained properly to avoid any issues. If worn, it must be replaced with new cables designed for your specific model to ensure optimal performance and safety.

- Clutch Alignment: A misalignment between the clutch plates can cause poor clutch engagement and reduced engine response when starting or stopping. Professional mechanics need to align your clutch plates properly. So you get optimal performance and safety on your Harley Davidson motorcycle.

- Clutch Plate Damage: Cracks or gouges in the clutch plate can cause uneven pressure and reduced engine efficiency when starting or stopping. These cracks can also lead to slippage, resulting in serious accidents if not repaired quickly.

Common Harley Davidson Hydraulic Clutch Problems And Solutions

Your Harley Davidson hydraulic clutch problems spring can be a great addition to your bike. But it’s also a complex part that requires regular maintenance and care. Four problems can occur with a Harley Davidson hydraulic clutch. They include seizing, sticking, slipping, and premature wear.

Harley Davidson, a renowned motorcycle manufacturer, has long been synonymous with power, performance, and iconic design. However, like any complex machinery, even the finest motorcycles are not immune to occasional issues. The hydraulic clutch system is one area of concern for Harley Davidson enthusiasts.

Sealing

Sealing means to close or secure a specific area or object to prevent the leakage of fluids, gases, or other substances. In the context of Harley-Davidson hydraulic clutch problems, sealing becomes crucial to ensure the efficient functioning of the clutch adjustment issues system. The hydraulic clutch system relies on properly sealing various components, such as the master cylinder, slave cylinder, and clutch line, to maintain the required pressure for smooth engagement and disengagement of the clutch.

Any issues with the seals in these components can lead to problems like fluid leaks and pressure loss. Or clutch slippage. Therefore, it is important to regularly inspect and maintain the seals in the hydraulic clutch system to prevent potential problems and ensure optimal performance of the Harley Davidson motorcycle.

Solutions

Sealing Solutions is a company that specializes in providing various sealing products and services. They offer various solutions for automotive, manufacturing, aerospace, oil and gas, and more industries. Their products include seals, gaskets, o-rings, and custom-designed sealing solutions to meet specific customer requirements.

Harley Davidson hydraulic clutch adjustment process problems and sealing solutions can be crucial in resolving issues. Properly functioning seals are essential for maintaining the hydraulic system’s integrity and preventing leaks that can lead to clutch problems. Sealing Solutions can provide high-quality seals designed to withstand the demanding conditions of Harley Davidson motorcycles.

Sticking

Sticking is a common issue that Harley Davidson enthusiasts may encounter with their hydraulic clutches. When a hydraulic clutch sticks, the clutch pedal or lever fails to return to its original position after being depressed. This can result in difficulty shifting gears, reduced clutch performance, and overall rider frustration. There are several potential causes for a hydraulic clutch to stick.

A possible reason is a problem with the clutch master cylinder or slave cylinder, such as leaks or air in the hydraulic system. Insufficient lubrication or contamination of the clutch components can also contribute to sticking.

Solutions

Sticking Solutions is a company that specializes in providing solutions for sticking or malfunctioning components in various industries. To address hydraulic clutch sticking issues, it is important to first check for any leaks or air in the system. If leaks are detected, repairing or replacing the faulty components may be necessary.

Slipping

Slipping is a common issue that Harley Davidson owners may experience with their hydraulic clutches. When the clutch slips, it means that the power from the engine is not being efficiently transmitted to the wheels. Resulting in a loss of acceleration and overall performance.

Various factors, including worn clutch inspection plates, a faulty clutch master cylinder, or air in the hydraulic system, can cause this problem. It is important to address slipping issues promptly, as they can lead to further damage and potential safety hazards. Seeking professional assistance from a Harley Davidson technician is recommended for diagnosing and resolving hydraulic clutch problems to ensure optimal performance and riding experience.

Solutions

To address hydraulic clutch slipping issues, it is important first to check the condition of the clutch plates. If they are worn or damaged, replacing them may be necessary.

Additionally, checking the clutch fluid level and ensuring it is at the proper level can help prevent slipping. If the fluid is low, adding more fluid can help restore proper pressure in the hydraulic system. Proper clutch cable or hydraulic system adjustment can also help prevent slipping.

How To Adjust A Hydraulic Clutch On A Harley Davidson

Proper tools and clutch adjustment are crucial for optimal performance and smooth operation of your Harley Davidson motorcycle. To adjust a hydraulic clutch on a Harley Davidson, follow these steps:

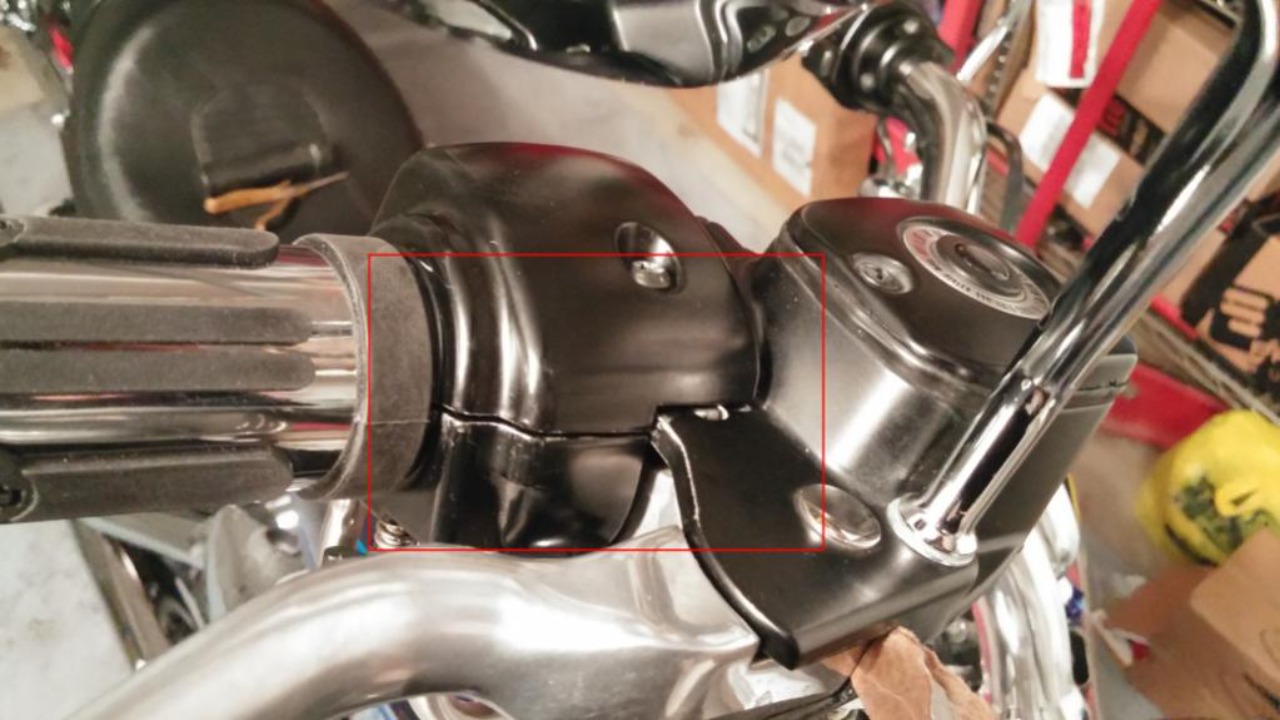

- Start by locating the clutch master cylinder, usually on the handlebars or the left side of the motorcycle’s engine.

2. Remove the cover from the master cylinder and check the fluid level. If it’s low, add the appropriate hydraulic fluid recommended by the manufacturer.

3. Find the clutch slave cylinder, typically located on the left side of the engine case.

4. Locate the clutch adjustment screw on the slave cylinder. You can usually turn this screw, which is a small bolt or nut, to adjust the clutch engagement.

5. Loosen the locknut on the clutch adjustment screw using a wrench or socket.

6. Turn the adjustment screw clockwise to increase clutch adjustment tools’ engagement or counterclockwise to decrease engagement. Make small adjustments and test the clutch feel after each adjustment.

7. Once you have achieved the desired clutch engagement, tighten the locknut securely.

8. Recheck the fluid level in the clutch release cover master cylinder and top it off if necessary.

9. Test the clutch by pulling the lever and shifting through the gears. Ensure that the clutch adjuster engages smoothly without any slippage or dragging.

10. If you encounter any difficulties or clutch problems persist, we recommend consulting a professional Harley Davidson mechanic or dealer for further assistance.

Tips For Maintaining The Harley Davidson Hydraulic Clutch

The hydraulic clutch on a Harley Davidson requires regular inspection and adjustment of the hydraulic fluid system for leaks, contact, or abrasion. It is vital to adjust clutch controls regularly to ensure sufficient spring tension and check for worn friction plates, warped frictions, or improper cable adjustment.

Over time, friction discs wear, and springs weaken, which may require replacing if the clutch master cylinder reservoir doesn’t engage properly. Following the manufacturer’s recommended service intervals and performing the necessary checks and adjustments are important to keep the hydraulic clutch action in good working order.

- Check the clutch fluid level regularly and replace any that is low or has started to leak.

- Adjust the clutch cover plates and tension as needed to achieve proper clutch engagement based on motorcycle-specific data provided by the manufacturer.

- Ensure all internal parts of the hydraulic clutch function correctly by checking for leaks, abrasions, incorrect adjustment, or wear.

- Always use an authorized service technician when maintaining your motorcycle’s hydraulic clutch.

Conclusion

A motorcycle clutch is an essential part of a motorcycle’s drivetrain. It allows the motorcycle to be driven by changing the pressure on the clutch pedal, thus changing the amount of power transmitted to the road. The clutch cable adjustment mechanism provides a smooth and consistent clutch feel, allowing you to change gears smoothly and with minimal effort. If your clutch feels stiff or gives inconsistent pressure, it could be a sign of Harley Davidson hydraulic clutch problems.

Suppose you’re having problems with your Harley Davidson hydraulic clutch. There is a good chance it is due to worn or damaged parts. Following this article’s instructions, you can replace the damaged or worn parts and restore your hydraulic clutch adjustment mechanism to its original condition. You can avoid needing a replacement or repair and keep your bike running smoothly and efficiently.

Frequently Asked Questions

What Are Common Hydraulic Clutch Problems?

Common hydraulic clutch problems include a low or leaking fluid level, air in the system causing a soft or spongy Harley Clutch Cable Adjustment pedal, a failing master or slave cylinder, or a worn or damaged clutch disc or pressure plate.

How Do You Know If Your Clutch Is Bad On A Harley?

A few common signs may indicate a bad clutch on a Harley. These include difficulty shifting gears, a slipping clutch that causes the engine to rev without power transfer to the wheels, a Clutch Adjustment Harley that engages too abruptly or releases too slowly, and a clutch cable tension that makes strange noises or vibrations.

How Do I Make My Harley Hydraulic Clutch Easier To Pull?

You can try adjusting the Harley Clutch Cable lever to a more comfortable position to make your Harley hydraulic clutch easier to pull. You can also check the fluid level in the clutch master cylinder and ensure it is at the appropriate level. If the fluid is low, you can add more to improve performance.

What Is The Most Common Problem Associated With Clutch?

The most common problem associated with a clutch is clutch slippage. This occurs when the clutch basket disc doesn’t fully engage with the flywheel, causing the engine’s power to not transfer efficiently to the transmission.

What Are The 5 Symptoms OF A Bad Clutch?

The five symptoms of a bad clutch are difficulty shifting gears, slipping clutch, clutch issue pedal feeling loose or spongy, clutch pedal sticking to the floor, and burning smell from the clutch.