The right pushrod adjustment on a Harley-Davidson motorcycle is essential for good performance. The pushrod is an important part of the valve actuation system, allowing the engine to run efficiently.

An incorrect or worn-out pushrod adjustment can cause poor performance, vibration and engine damage. Taking the time to make sure the pushrods are correctly adjusted is essential for long-term reliability and optimum performance. And you can do it efficiently by following the Harley pushrod adjustment chart to get optimum performance.

However, we’ll discuss the importance of pushrod adjustment and provide a chart to help you get the most out of your Harley. We’ll review the importance of properly adjusting the pushrod and what can go wrong if it’s not set correctly. We’ll also provide a quick reference chart to ensure you can quickly and easily adjust the pushrod without any guesswork.

Accessing The Harley Pushrod Adjustment Chart

The purpose of pushrod adjustment is to help ensure that the engine cold valves open and close at the right time and with the right amount of force. An improperly adjusted pushrod can result in poor engine performance and excessive wear on the valvetrain components.

The Harley pushrod adjustment chart provides a guide to adjusting the pushrods correctly. You can use the chart to determine the required pushrod length and the ideal setting for the pushrod adjustment. Using the chart and properly adjusting the pushrods is important to ensure the engine runs optimally.

| Pushrod Length | Intake Valve Adjustment | Exhaust Valve Adjustment |

| 9.750″ | 0.185″ | 0.215″ |

| 9.880″ | 0.195″ | 0.225″ |

| 10.010″ | 0.205″ | 0.235″ |

| 10.140″ | 0.215″ | 0.245″ |

| 10.270″ | 0.225″ | 0.255″ |

| 10.400″ | 0.235″ | 0.265″ |

| 10.530″ | 0.245″ | 0.275″ |

| 10.660″ | 0.255″ | 0.285″ |

| 10.790″ | 0.265″ | 0.295″ |

| 10.920″ | 0.275″ | 0.305″ |

Accessing the Harley-Davidson pushrod adjustment chart is essential for any motorcycle owner. The chart provides the necessary information to ensure that the engine is running at its optimal performance. It outlines the various factors you must take into consideration when adjusting the pushrods, such as the type of engine, the model, the year, and the displacement.

This information allows the user to determine the correct tension for the pushrods and helps to ensure that the engine runs smoothly and efficiently. By following the instructions provided in the chart, users can make sure that their engine is running at its best, providing a smooth ride and maximum performance.

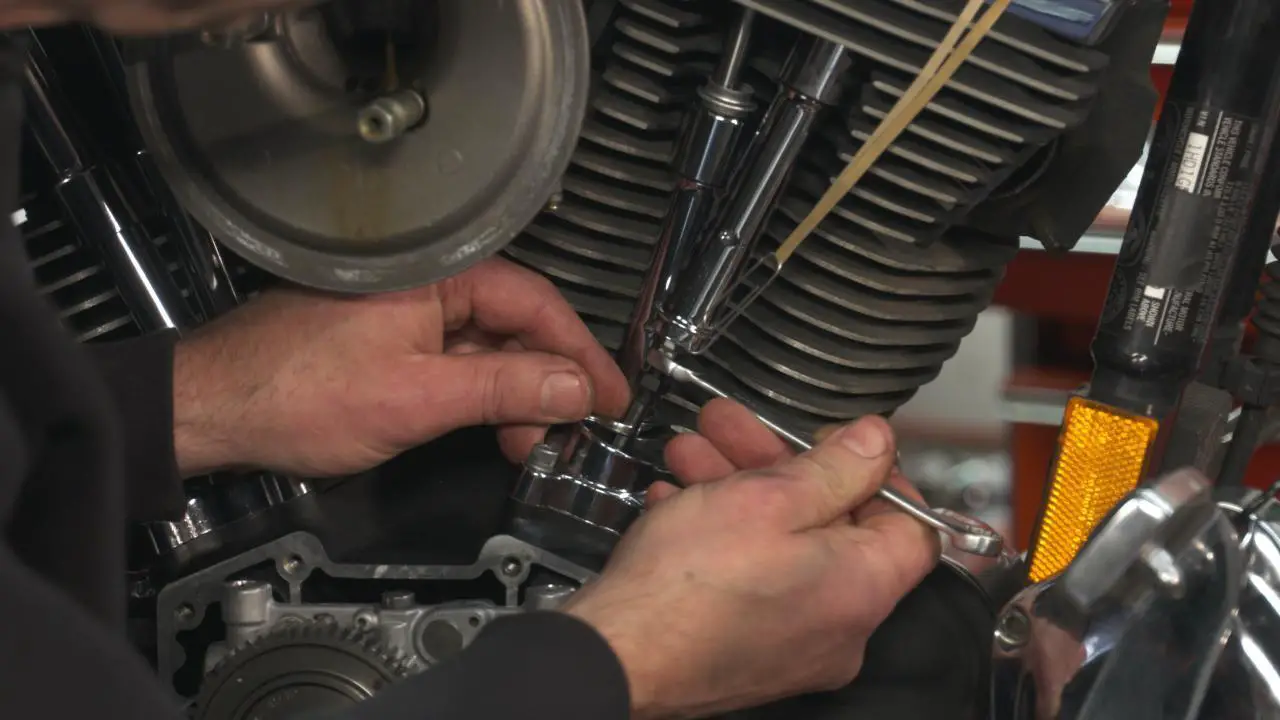

Step-By-Step Guide To Adjusting Pushrods On Harley-Davidson Motorcycles

The Harley Pushrod-Adjustment Chart is a valuable tool for motorcycle enthusiasts and mechanics alike. This chart provides crucial information and guidance on how to properly adjust the pushrods on Harley-Davidson motorcycles. The pushrods play a vital role in the engine’s performance and overall operation, ensuring proper valve timing and optimal power output. The method for adjusting pushrods on a Harley is essential for maintaining proper engine performance. Here are 5 Steps to Adjusting Pushrods on Harley-Davidson Motorcycles:

1. Preparing The Motorcycle For Adjustment

Adjusting the pushrods on Harley-Davidson motorcycles is an essential maintenance task that ensures proper valve timing and optimal engine performance. To begin this process, it is crucial to prepare the motorcycle for adjustment. This involves several steps to ensure that the engine is in the correct lowest position and ready for precise adjustments. Firstly, make sure the motorcycle is on a level surface and securely supported. This will prevent any accidental movement or instability during the adjustment process.

Safety should always be a top priority when working on any vehicle. Next, remove any necessary components that may obstruct access to the upper pushrod covers. This may include removing the gas tank, rocker box covers, or other parts that are in the way. Take caution and refer to the motorcycle’s service manual for specific instructions on component removal.

2. Locating And Accessing The Pushrods

Once you have gathered all the necessary tools and equipment, you are ready to move on to the next step – locating and accessing the pushrods on your Harley-Davidson motorcycle. This step is crucial in ensuring proper adjustment and optimal performance of your bike’s engine. To begin, carefully remove any necessary components or covers that may be obstructing your access to the pushrods. This may include removing the air cleaner assembly, rocker box covers, or any other parts that may be in the way.

Take your time and ensure that you have a clear view of the pushrods. Next, identify the pushrod tubes or covers. These are typically located on the top of the engine, running parallel to the cylinders. Depending on your specific Harley-Davidson model, you may have either two or four pushrods. Take note of their position and make sure to keep track of which pushrod corresponds to which cylinder.

3. Measuring Pushrod Length

To begin this process, carefully remove the retainers on pushrod covers and locate the pushrods themselves. Take note of the specific specifications provided by the manufacturer for your particular model. Using a reliable pushrod measuring tool, carefully place it on the pushrod to get an accurate reading. Ensure that the tool is aligned properly and that it is not skewed, as this may result in incorrect measurements. Gently push rod the tool down until it firmly contacts the tip of the pushrod.

Next, take note of the measurement displayed on the tool. Compare this measurement to the specifications provided by the manufacturer. If the measured length falls within the recommended range, you can proceed to the next step. However, if the measurement is outside of the specified range, adjustments will be necessary.

4. Adjusting Pushrod Length

Once you have located the pushrods on your Harley-Davidson motorcycle, it is important to ensure that their length is properly adjusted. This step is crucial in maintaining optimum engine performance and overall functionality. To begin, carefully remove the pushrod covers to gain access to the pushrods themselves.

Take note of the existing length of each pushrod, as this will serve as a reference point during the adjustment process. Next, using a pushrod adjustment tool, carefully rotate the pushrod adjusting screw in a clockwise or counterclockwise direction to either increase or decrease its length. It is important to make small adjustments at a time, ensuring that you do not overtighten or loosen the pushrods.

5. Reassembling And Checking For Proper Adjustment

After carefully adjusting the pushrods on Harley-Davidson motorcycles, we move onto the crucial step of reassembling the components and checking for proper adjustment. This step ensures that the pushrods are correctly aligned and functioning optimally, guaranteeing smooth and efficient engine performance. First, we begin by placing the pushrod covers back onto the pushrods.

It is important to ensure that they are securely fastened to prevent any potential leaks or malfunctions. Next, we carefully reinstall the rocker covers, making sure they are properly aligned and tightened to the manufacturer’s specifications. Once the reassembly is complete, we proceed to check for proper adjustment. This involves carefully inspecting the pushrods to ensure they are correctly seated in the lifter plungers and rocker arms. We also check for any signs of excessive play or tightness, as these could indicate improper adjustment.

Common Mistakes To Avoid During Pushrod Adjustment

A bolt cutter is a versatile tool used for cutting through thick and heavy materials, such as chains, padlocks, and metal rods. Metal debris can be a common issue when working with machinery, particularly in heavy industries such as manufacturing or construction. Battery cables are essential components in a vehicle’s electrical system, responsible for transmitting power from the battery to various electrical components. Common Mistakes to Avoid during Pushrod Adjustment on Harley-Davidson Motorcycles:

- Incorrect Valve Lash: One common mistake is not setting the correct valve lash during pushrod adjustment. It is crucial to follow the manufacturer’s specifications for the specific model and engine type. Failing to do so can result in poor engine performance and potential damage to the valves or lifters.

- Over-Tightening Or Under-Tightening: Another mistake is either over-tightening or under-tightening the pushrods. Over-tightening can lead to excessive valve train noise, premature wear, and possible engine Severe damage. Under-tightening can cause valve train noise, poor performance, and potential valve float at high RPMs.

- Inconsistent Adjustments: It is important to ensure consistent adjustments for all pushrods. Failing to do so can lead to imbalanced valve performance, resulting in poor engine operation, misfires, and potential damage.

- Ignoring Proper Sequence: Following the correct sequence while adjusting pushrods is essential. Ignoring this sequence can lead to improper valve timing, loss of power, and potential engine damage. Always refer to the service manual or manufacturer’s guidelines for the correct order.

- Lack Of Proper Tools: Not using the proper tools can also lead to mistakes during pushrod adjustment. It is recommended to use specialized tools like pushrod adjustment wrenches or feeler gauge thread gauges to ensure accurate measurements and proper adjustment.

Recommended Adjustment Range for Pushrods

The recommended adjustment range for pushrods on Harley-Davidson motorcycles can vary depending on the specific model and engine. However, as a general guideline, it recommend to adjust pushrods within a range of 0.100 to 0.150 inches of lifter preload.

This range ensures proper valve train operation and allows for optimal performance and longevity of the engine. It is important to consult the manufacturer’s specifications or a qualified technician for the specific adjustment range for your Harley-Davidson motor model. The mechanic marked the pushrod with a permanent marker for future reference.

Importance Of Pushrod Adjustment

The importance of pushrod adjustment in a vehicle’s engine that we can’t overstate. Adjusting pushrod length correctly helps to ensure that the valvetrain operates correctly, allowing for maximum performance and efficiency. In addition, proper head intake lifter pushrod hole adjustment also helps to reduce wear on components and eliminate problems such as valvetrain noise.

Adjusting the pushrods correctly requires specialized tools and knowledge of the engine. We highly recommend performing any pushrod adjustment by a certified technician. The clearance values mentioned in the Harley Pushrod-Adjustment Chart are crucial for maintaining optimal performance and preventing any potential engine issues.

Conclusion

Overall, pushrod adjustment on Harley-Davidson engines is important in ensuring your bike runs smoothly and efficiently. Following the steps, you can easily access the official Harley pushrod adjustment chart and understand the importance of pushrod adjustment for your bike. Pushrod adjustment is an important aspect of maintaining a Harley-Davidson engine.

It recommends to consult the Harley-Davidson pushrod adjustment chart and understand the basics of pushrod adjustment to ensure that the engine is running at its best. It is also important to remember to check the pushrod adjustment regularly to prevent any problems from occurring in the future. With regular adjustments, you’ll be able to enjoy your Harley-Davidson for years to come.

Frequently Asked Questions

How Do You Adjust A Pushrod?

To adjust a pushrod, first, make sure the engine is cool. Then, remove the valve cover and locate the cylinder’s pushrods. Using a wrench or socket, loosen the rocker arm lock nut until you can spin it with your fingers. Next, spin the pushrod with your fingers to feel any resistance or play.

Which Pushrod Is Longer On Harley?

The intake pushrod is typically longer on Harley-Davidson motorcycles compared to the exhaust pushrod. This longer length helps ensure a proper and optimal intake lifter valve lift, which directly impacts the engine’s overall power and efficiency.

What Effects Pushrod Length?

Pushrod length can have a significant impact on valve timing and engine performance. A longer exhaust pushrod can increase valve lift and duration, while a shorter pushrod can decrease them.

What Happens If Pushrods Are Too Short?

If pushrods are too short, they may not be able to properly engage with the rocker arms or lifters, resulting in inadequate valve lift and potentially causing poor engine performance or damage.

How Do You Determine Pushrod Length?

Pushrod length is typically determined by measuring the distance between the rocker arm and the lifter when the valve is fully closed. This measurement can be done using a pushrod length checker tool or by using adjustable rear cylinder pushrods to find the correct length.