Harley Davidson has been a household name in the motorcycle industry for over a century, known for its iconic designs and powerful engines.

However, even the most well-crafted machines can experience issues, and one common problem faced by Harley Davidson 103 owners is with the Compensator. The compensator is a crucial component in the motorcycle’s drivetrain, reducing engine vibration and providing a smooth ride.

Compensators are a vital part of any motorcycle’s engine. They allow smooth airflow from the exhaust pipe into the engine and improve performance by modifying exhaust gases’ direction and velocity. Without compensators on your motorcycle, your ride could get noisy or suffer from reduced power output. Here, we will cover everything you need about how to fix Harley Davidson 103 compensator problems. How to avoid those, and what to look for when checking or fixing them.

What Is Harley Davidson Compensator

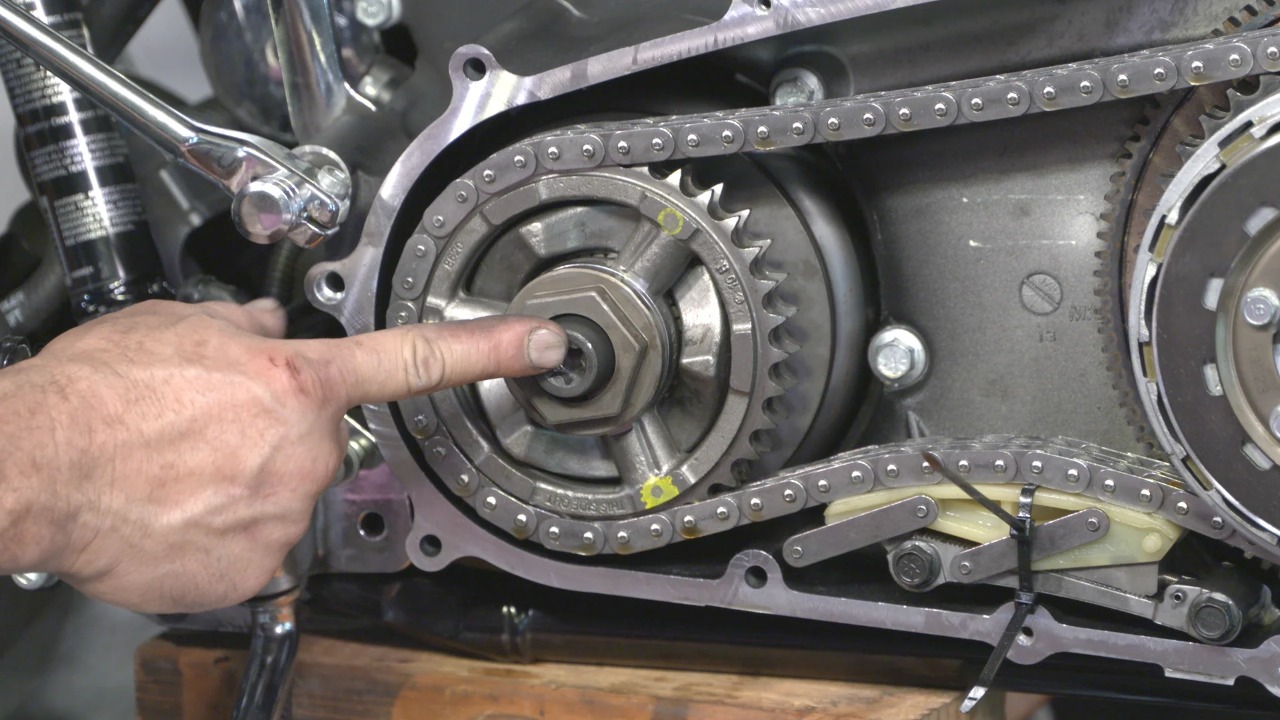

A Harley-Davidson compensator is a vibration dampener that absorbs the violent torque coming from the engine and transfers it further to the transmission. It is important to protect the chain, clutch pack, or transmission from damage. The primary chain tensioner, design flaws, and ride quality are common signs of the Harley Davidson compensator’s issues, leading to innovative solutions such as the Hayden Enterprise.

A compensator helps reduce clutch and transmission pressure when torque is applied abruptly by the engine. Its job is to absorb violent torque from the engine and transfer it further to the transmission. Engineers design them with springs to support large torque, particularly for high-displacement and high-compression engines. A compensator is an essential component that you must include in any tuned twin-cam engine setup.

What Are The Signs Of A Worn Out Harley Compensator?

Harley-Davidson motorcycles are popular for their powerful engines and exceptional performance on the road. However, over time, certain components can wear out, affecting the overall functionality of the bike. One such component is the Compensator, a vital part of the Harley engine that helps to counteract the torque generated by the engine. So, what are the signs of a worn-out Harley compensator? Here are some key indicators that riders should be aware of:

- Excessive noise

- Vibrations

- Difficulty shifting gears

- Slack in the primary chain

- Engine backfiring

- Poor performance

- Oil leaks

- Excessive clutch noise

- Difficulty starting the bike

How To Fix Harley Davidson 103 Compensator Problems

The 103 Compensator is a type of valve installed on an engine’s exhaust side to increase power and efficiency. It’s also known as a camshaft compensator or a valvetrain compensator. It’s typically made of metal and consists of several lobes that can be adjusted to change the airflow and fuel to the engine.

How to fix Harley Davidson 103 compensator problems is a motorcycle exhaust system with a slip-streaming effect to reduce rear wheel torque and decrease engine RPM. This system is often used on bikes with high-output engines, such as V-twins, to help balance the torque curve and improve performance. Unfortunately, many riders report problems with their HD103 compensators, including:

Rattling Or Clanking Noises When The Bike Is Idling Or In Neutral

If you hear a rattling or clanking noise when the bike is idling or in neutral, there could be a problem with your 103 Compensator. The 103 comp has a camshaft that causes it to spin at high speeds and generate sound. A loose or damaged camshaft can result in this issue. If so, you should have your 103 replaced as soon as possible.

Another possible solution for this issue could be to replace the rubber o-ring that holds the camshaft in place with an adhesive silicon seal. This seal will create a better seal between the camshaft and the housing and prevent it from moving around, which could lead to more rattling noises. If none of these solutions work, consider having your 103 replaced by a professional mechanic specializing in Harley Davidson 103 Compensator repairs.

Engine Hesitation Or Stalling

Several potential issues can cause engine hesitation or stall. The most common issues include worn or damaged valves, cylinder heads, or piston rings that reduce the engine’s compression ratio. This can lead to reduced power and increased fuel consumption.

A damaged valvetrain can create lifter float issues, which may cause hesitation and stall under certain circumstances. A worn camshaft can also affect the engine’s performance, creating stuttering as the valves open and close. Finally, when needed, a misfiring ignition coil may prevent the spark from igniting properly. These issues may be difficult to identify or fix on your own, so it’s important to have them repaired by a professional technician.

Poor Acceleration

The Compensator is one of the two throttling valves on a Harley Davidson 103 engine. They install it between the intake and exhaust valves. The purpose of a compensator is to remove air from the intake manifold as the throttle is opened, resulting in a higher air-mass-air-fuel ratio (MAF) and richer fuel mixture in the cylinders. Using a slide that opens and closes causes an acceleration in the MAF. This can result in poor acceleration when a compensator fails or becomes damaged.

A damaged or faulty compensator can cause poor acceleration due to a lack of oxygen entering the cylinder. A compromised or damaged Compensator will affect your motorcycle’s performance and fuel efficiency, which could lead to costly repairs. If you notice any of these signs while driving your bike, it’s best to get it checked at a mechanic. Worn or damaged parts may cause these symptoms in the hd103 compensator system.

Damaged Or Malfunctioning Valves Causing Poor Combustion

Damaged or malfunctioning valves are one common cause of Harley Davidson 103 compensator problems. When the valves are not functioning properly, it can lead to poor combustion, which can affect the performance and smoothness of the ride.

To fix this issue, have a professional inspect and service the primary cover and compensator kit. Aftermarket compensator shock absorbers can help minimize the impact of bad compensator sounds, addressing the compensator challenges posed by damaged or malfunctioning compensator components and ultimately leading to improved combustion.

They will be able to identify any issues with the valves and make the necessary repairs or replacements. This will help restore the proper functioning of the Compensator and ensure a smoother ride for your Harley Davidson 103.

How Does The Compensator Work On A Harley

The Compensator on a Harley Davidson is a critical component of the engine’s design. It helps to reduce the impact and stress on the transmission and primary drive system, resulting in smoother operation. The stock compensator can sometimes develop issues over time, leading to bad compensator symptoms such as excessive noise, vibration, or even failure.

In such cases, replacing the compensator sprocket may be necessary, or consider installing a compensator eliminator kit for a more durable solution. Highly recommended to diagnose and address compensator problems effectively, consult with a qualified mechanic.

Benefits Of Upgrading A Bad Compensator

Upgrading a faulty compensator brings numerous benefits. By investing in newer models, you ensure better performance and longer lifespan. The improved bearings and advanced rotor design enhance stability and reduce vibrations.

Upgraded compensators also eliminate issues like shaft misalignment and level discrepancies. With a reliable compensator, you can prevent costly failures and minimize downtime. Following the instructions in the service manual guarantees proper installation and optimal functionality.

Cost Of Compensator Upgrade

The cost of the compensator upgrade includes the techs’ labor and the installation adhesive kit, specifically the P/N 11100088. It is important to note that the compensator may require a separate purchase. However, this upgrade is worth considering as it prevents premature wear and ensures a factory-style compensator.

Additionally, the starter mechanism will also benefit from this upgrade, providing improved performance and reliability. In general, compensator upgrades can range from a few hundred to several thousand dollars. This cost includes the price of the new compensator and any additional components or equipment needed for the upgrade. It may also include labor costs if professional installation is required.

Conclusion

Knowing how to fix Harley Davidson 103 compensator problems is essential for maintaining the performance and longevity of your bike. By addressing issues with the original Compensator, clutch hubs, chain tensioner, primary chain, and other components, you can ensure a smoother ride and prevent further damage to your motorcycle.

Whether you tackle these repairs yourself or seek assistance from a professional service manager, it’s important to address them promptly. By taking the necessary steps to fix compensator problems, you can continue enjoying the thrill of riding your Harley Davidson 103 for years to come.

Frequently Asked Questions

How Does A Harley Compensator Work?

The Harley compensator is a part of the primary drive system in Harley-Davidson motorcycles. The engine crankshaft connects the Compensator or starter ring gear and engages it with the starter motor to start the engine.

What Does A Compensator Eliminator Do For Harley?

A compensator eliminator for a Harley is a device that removes the compensator sprocket from the primary drive system. This can help reduce noise and vibration caused by the compensator assembly, resulting in a smoother ride.

Is A Harley Compensator Nut Reverse Thread?

No, the compensator nut on a Harley-Davidson is not a reverse thread. Turn it clockwise to tighten and counterclockwise to loosen; it is a regular right-hand thread.

What Does A Compensator Do On A Bike?

A compensator on a bike is a device that helps reduce the effects of engine torque on the drivetrain. It helps smooth out power delivery and minimize vibration by absorbing and counterbalancing engine forces.

What Is The Reason For A Compensator?

A compensator is handy in control systems to improve performance by reducing or eliminating errors and disturbances. It adjusts the input signal in response to changes in the output signal, helping to achieve desired system behavior and stability.